:quality(80))

Materials Science Jobs Skills Radar 2026: Emerging Tools, Techniques & Technologies to Learn Now

From next-generation batteries and biodegradable plastics to semiconductors and smart composites, materials science sits at the core of UK innovation. As we move into 2026, demand for skilled materials scientists is growing rapidly across sectors including aerospace, electronics, energy storage, biomedical engineering, and sustainable manufacturing.

Welcome to the Materials Science Jobs Skills Radar 2026—your annual guide to the software, laboratory tools, modelling platforms, and practical skills most in demand for materials science roles in the UK. Whether you’re in R&D, failure analysis, manufacturing, or academic research, this radar helps you stay relevant in a competitive and evolving field.

Why Materials Science Skills Are Changing in 2026

The materials field is becoming increasingly interdisciplinary. Employers now expect professionals who can:

Operate complex characterisation instruments

Use simulation tools to model stress, heat, and reactivity

Design and test advanced materials for extreme environments

Work fluently across physical labs and digital workflows

Analyse, visualise, and communicate high-dimensional datasets

UK labs and industrial R&D centres also want candidates who understand scaling, sustainability, compliance, and IP awareness.

Top Experimental Techniques to Learn in 2026

1. Scanning Electron Microscopy (SEM)

What it is: A high-resolution imaging method for surface topography and composition.

Why it matters: SEM is standard across failure analysis, corrosion testing, and microstructure analysis.

Used by: Rolls-Royce, UK universities, advanced composites companies.

Roles: Materials Analyst, Failure Investigator, SEM Technician.

Skills to pair: EDX (energy-dispersive X-ray), sample prep, sputter coating.

2. X-Ray Diffraction (XRD)

What it is: Technique to study crystal structure and phase composition.

Why it matters: Used in metallurgy, batteries, semiconductors and pharmaceuticals.

Used by: Johnson Matthey, Oxford Instruments, defence labs.

Roles: Crystallographer, Structural Materials Scientist.

Skills to pair: Rietveld refinement, lattice strain analysis, sample mounting.

3. Thermal Analysis (TGA, DSC, DMA)

What it is: Tools that measure changes in material properties under heating or cooling.

Why it matters: Crucial for polymers, thermoplastics, curing systems, thermal stability.

Used by: Aerospace and automotive firms, adhesive R&D, packaging.

Roles: Thermal Analyst, Polymer Scientist.

Skills to pair: Transition temp analysis, rate-dependent profiles.

4. Mechanical Testing

What it is: Stress, strain, hardness, impact, fatigue and creep testing under various loads.

Why it matters: Essential in materials qualification, QA and certification.

Used by: Structural engineering, defence contractors, infrastructure labs.

Roles: Mechanical Testing Engineer, QC Analyst.

Skills to pair: Tensile testing, fracture mechanics, digital image correlation (DIC).

5. Spectroscopy (FTIR, Raman, UV-Vis)

What it is: Chemical fingerprinting and bond structure analysis tools.

Why it matters: Used in biomaterials, polymers, coatings, and trace analysis.

Used by: Diagnostics, food science, chemical materials firms.

Roles: Analytical Scientist, Chemometrician.

Skills to pair: Spectral deconvolution, baseline correction, PCA.

Top Digital & Simulation Tools to Learn

1. MATLAB

What it is: A flexible platform for data analysis, modelling, and simulation.

Why it matters: Still widely used in academia and applied research for materials data and curve fitting.

Used by: Universities, aerospace R&D, thermal design teams.

Roles: Research Engineer, Materials Modeller.

Skills to pair: Simulink, optimisation, script automation, COM interfaces.

2. COMSOL Multiphysics

What it is: FEA software for multiphysics modelling—heat transfer, electromagnetics, stress.

Why it matters: Excellent for battery systems, MEMS, coatings, and structural coupling.

Used by: Medtech and clean energy firms, universities, sensors companies.

Roles: Simulation Scientist, Multiphysics Modeller.

Skills to pair: Geometry setup, meshing, physics coupling.

3. ANSYS / Abaqus

What it is: Industry-standard platforms for finite element analysis (FEA).

Why it matters: Used for stress-strain simulations, thermal cycling, fatigue and crash simulations.

Used by: BAE Systems, Jaguar Land Rover, nuclear fusion centres.

Roles: FEA Engineer, Structural Modeller.

Skills to pair: Material card selection, boundary conditions, convergence checks.

4. Python for Materials Science

What it is: A language for scripting automation, data science and computational materials workflows.

Why it matters: Growing fast in academia and industrial labs using high-throughput screening and AI.

Used by: Materials Project, UK HPC centres, startups.

Roles: Computational Materials Scientist, Materials Informatics Specialist.

Libraries to learn: NumPy, Pymatgen, ASE, Matplotlib, scikit-learn.

5. OriginLab / Minitab / JMP

What it is: Graphical and statistical data analysis tools used in lab reporting and QA.

Why it matters: Widely used in regulated industries for reliability, process control and method validation.

Used by: Pharma, medtech, manufacturing.

Roles: Quality Analyst, Lab Scientist.

Skills to pair: DoE, ANOVA, regression, control charts.

Emerging Technologies & Computational Materials Science

▸ Pymatgen + Materials Project

For crystal structure analysis, high-throughput screening, and feature extraction.

▸ Matminer

ML feature toolkit for material property prediction models.

▸ AFLOW / OQMD / JARVIS Datasets

Used in ML for materials design and property prediction.

▸ Additive Manufacturing (3D Printing)

Software: Autodesk Netfabb, Cura, Fusion 360.

Used in: Aerospace components, implants, dental prosthetics.

▸ 2D Materials & Metamaterials

Applications: Photonics, flexible electronics, wearables.

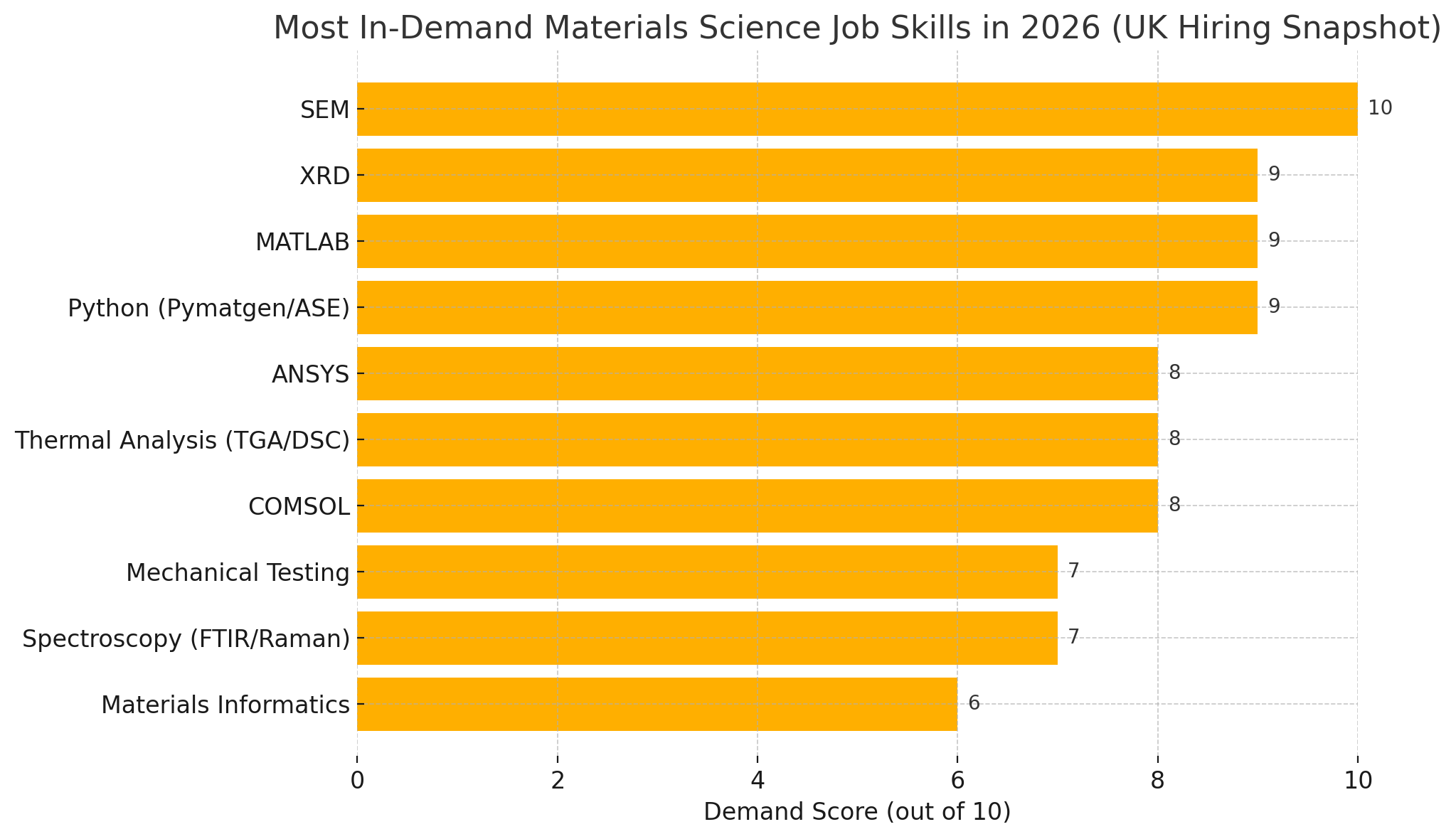

Most In-Demand Materials Science Job Skills in 2026 (UK Hiring Snapshot Forecast)

Here’s a visual overview of the tools, platforms & techniques UK employers are prioritising:

How to Future-Proof Your Materials Science Career in 2026

How to Future-Proof Your Materials Science Career in 2026

Master Core Characterisation Techniques

SEM, XRD, and spectroscopy are baseline requirements across lab-based roles.Learn One Modelling Platform + Python

Combining COMSOL or ANSYS with Python gives you a competitive edge in simulations.Understand Data-Driven Materials Discovery

Explore machine learning libraries, materials informatics tools, and open datasets.Build Hands-On & Computational Fluency

UK employers favour candidates who can move seamlessly from lab to laptop.Engage with UK Networks

Join IOM3, attend Materials Research Exchange, UK Battery Industrialisation Centre events & academic-industry initiatives.

Where to Find Materials Science Jobs in the UK

🔬 Visit www.materialssciencejobs.co.uk to browse UK roles in applied R&D, product design, manufacturing, energy, aerospace, and nanomaterials.

Conclusion: Your Materials Science Toolkit for 2026

Materials science is advancing rapidly—and the best careers will go to professionals who can combine experimental expertise with digital innovation. Whether you're characterising new alloys, developing nanocoatings, or building polymer simulations, staying current is key.

Use this Materials Science Jobs Skills Radar 2026 to shape your learning and job strategy—check back yearly for updates on what’s driving demand in UK materials careers.

Subscribe to our newsletter for job alerts, funding news, and technical upskilling resources.