Pre-Employment Checks for Materials Science Jobs: DBS, References & Right-to-Work and more Explained

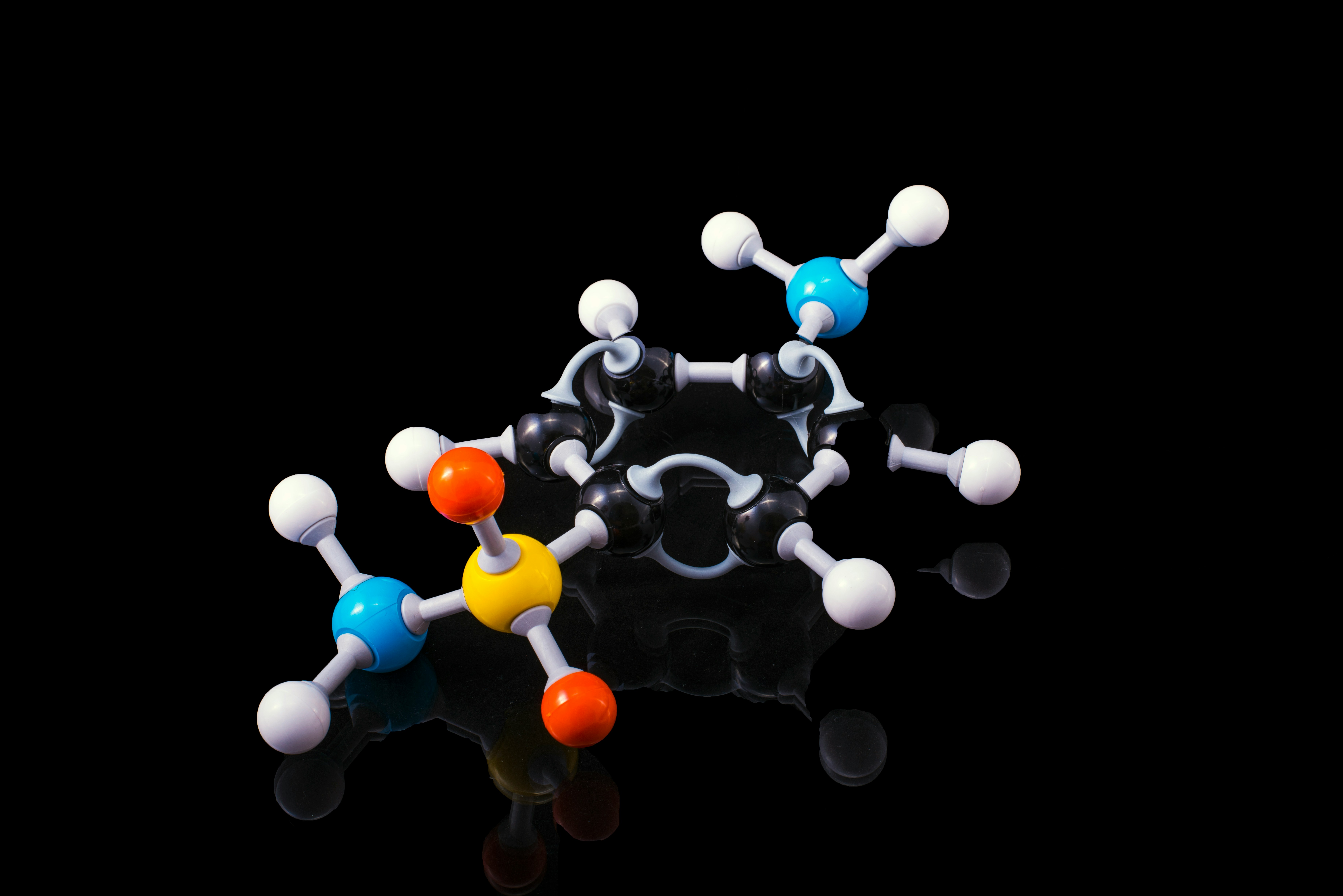

Pre-employment screening in materials science reflects the discipline's unique position at the intersection of advanced manufacturing, nanotechnology innovation, and critical materials development. Materials scientists often have privileged access to proprietary formulations, cutting-edge research data, and strategic materials technologies that form the foundation of organisational competitive advantage and technological leadership across multiple industries. The materials science industry operates within complex regulatory frameworks spanning chemical safety directives, nanotechnology governance requirements, and emerging advanced materials regulations. Materials science professionals must demonstrate not only technical competence in materials characterisation and development but also deep understanding of chemical safety protocols, environmental impact assessment, and the societal implications of advanced materials deployment at scale. Modern materials science roles frequently involve developing materials for aerospace applications, biomedical devices, energy storage systems, and advanced manufacturing processes across multiple regulatory jurisdictions and safety frameworks simultaneously. The combination of chemical expertise, materials innovation capabilities, and industrial application responsibility makes thorough candidate verification essential for maintaining compliance, safety, and technological leadership in materials-driven industries.